Materials

Fibreglass Fabric / Mat

Fibreglass is a common type of fiber-reinforced plastic using glass fiber. The fibers come in different arrangements and may be randomly arranged, flattened into a sheet (chopped strand mat), or woven into a fabric.

Fibreglass comes in many different weights and thicknesses. The weight of fibreglass is measured in grams per square meter or GSM2

Common fiberglass used in blade construction and repair

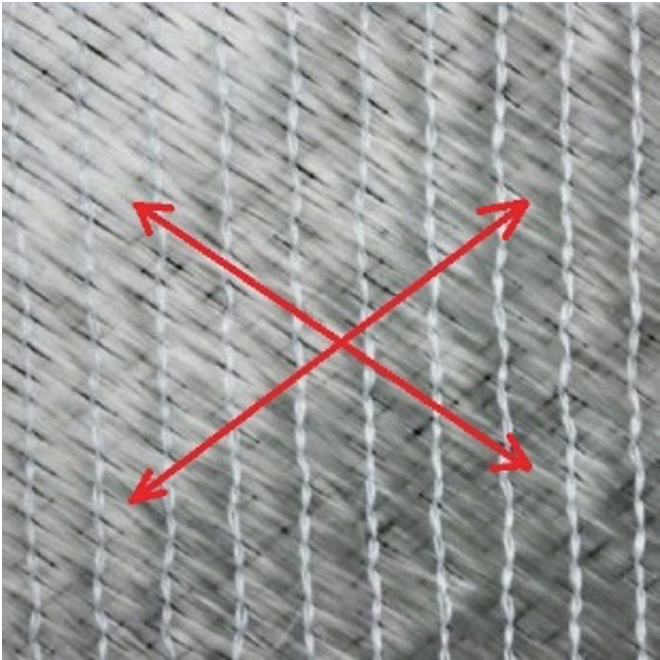

Biaxial fibreglass

Biaxial is a (+/-45 degree) Cloth The fiberglass tows are held together by light nylon stitching which do not affect the structural integrity of the cloth. Red arrows indicate the fiber directions.

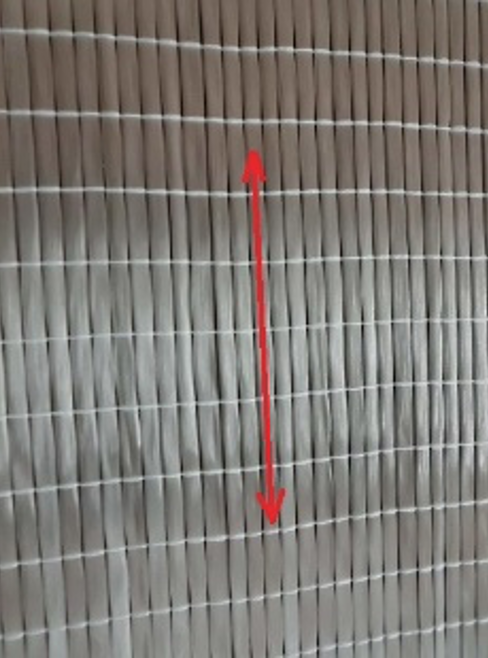

Unidirectional fibreglass cloth (1 direction)

Unidirectional fibreglass cloth is a fibreglass is woven in such a way that the fibres are orientated in one direction. When layered with resin this cloth will have excellent strength lying mainly in one direction.

Triaxial fibreglass cloth (3 directions)

Triaxial fibreglass cloth is a (0, and +/-45 degree) type of weave. Triaxial fibreglass combines the benefits of both standard +/-45 degree biaxial and unidirectional fibreglass. The fiber tows run in perpendicular angles to add strength and reduce both torsional and longitudinal flexion and strain.

Chopped strand mat (random direction)

Fibreglass Mat, also known as Chopped Strand Mat or CSM. This is a non-woven material typically used for laminate build-up and repair work. It consists of glass fibres laid randomly across each other and held together by a styrene binder that dissolves when wetted out.

Peel Ply

Peel ply is a lightweight fabric that is laid over the wetted-out reinforcement, then more resin is applied using a squeegee to wet out the peel ply. After the lamination cures it is then removed, the result is a slightly textured, surface. Peel ply is also used when additional bonding and finishing operations are needed. E.g. applying fillers

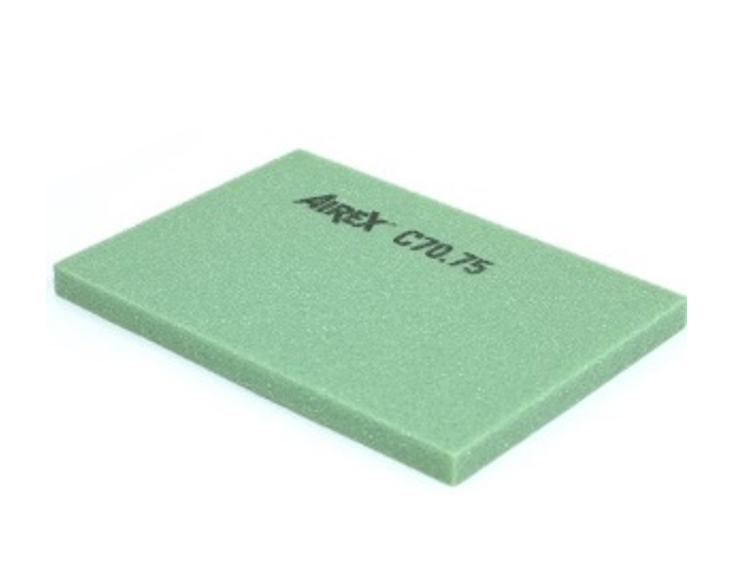

PVC foam core (Polyvinyl chloride)

PVC foam combines excellent stiffness and strength to weight ratios with superior toughness. This core material is used for a wide variety of sandwich structures subjected to both static and dynamic loads. Available in different sizes and thickness.

P.E.T foam core (Polyethylene terephthalate)

PET foam core is used extensively in wind turbine production as well as many more areas. Its benefits include high strength to weight ratio, thermal stability and insulation as well as acoustic insulation properties. Available in different sizes and thickness.

Balsa

Balsa is very light weight ridged material that, when scored and combined with a scrim fibre backing it is Flexible which allows itself to easily conform to curves. Balsa suits applications which specify high structural requirements with reduced weight and good cost effectiveness. Applications include wind turbine blades, marine hulls and decks, bulkheads, superstructures, floors and interiors.